Ozone for bottling plant

Ozone is widely used in bottled water for filling water and bottle and cap washing. A certain concentration of ozone is dissolved into the water, with enough contact time will make sure the disinfection effect.

Spring water requires tight control of the concentration of ozone to ensure a consistent balance between sanitation and bromate formation. The ozone dose and contact time must be sufficient to inactivate bacteria, virus and parasites that might be present in the product during bottling. However, the ozone dosing parameters must be controlled to minimize conversion of bromide ion to bromate. (Under certain conditions, naturally occurring bromide ion may be oxidized to bromate ion a regulated chemical.)

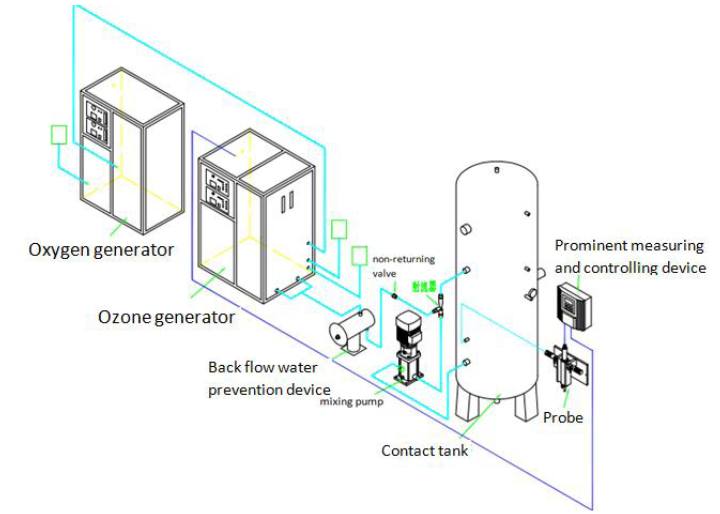

Maintaining tight control of ozone dosing at final bottling presents unique challenges. Variables that impact the concentration of dissolved ozone include water temperature, flow rate, ozone generator output, mass transfer efficiency and system hydraulic retentention time. Below is a simple diagram of our solution for the consistent concentration of dissolved ozone in the water:

The measuring and controlling device comes with dissolved ozone concentration sensor and the controller will be sending a 4-20mA signal to the ozone generator according to the dissolved ozone concentration. Then ozone generator will regulate its output according to the algorithm, ensuring correct concentration of ozone from its outlet. And dissolved ozone concentration will be consistent by this close-loop control.

Below is a simple diagram:

Previous: CIP

Next: Aquaculture

Becodrive Company Limited

Tel:4006-846-876

E-mail:ozone.qaos@hotmail.com

Web:www.becodrive.com

Add:1th Liulian Road, Jianggao, Baiyun, Guangzhou